Kraissl Transfer Valves are used to “parallel” or duplex two pieces of pipeline equipment in continuous flow without shut off of either one. Examples include duplexing of two heat exchangers, filters or tanks. These rugged units are time tested for many years in a wide variety of fluid applications.

APPLICATION

Transfer valves are available in 3/4 through 8 inch sizes in ANSI flange classes 150, 300, 400, 600, 900,1500 and higher. Special ring joint flanges can also be furnished. They provide a simple, cost effective way to duplex flow equipment for applications where continuous flow must be maintained, with no flow interruption for down-side servicing.DESIGN SPECIFICATIONS

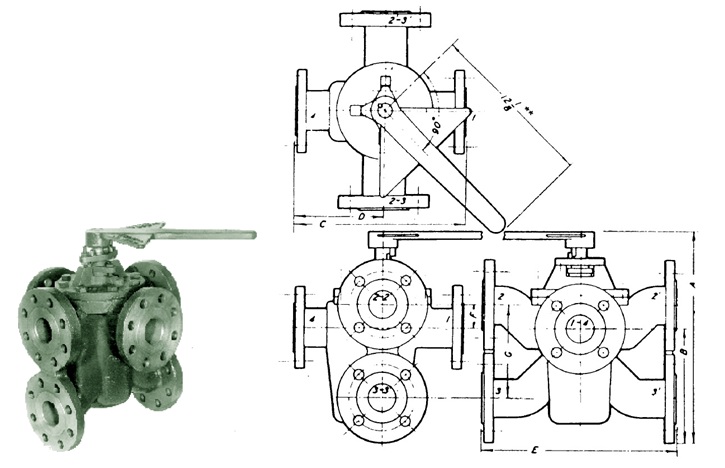

Model 72AAF(H)S series transfer valves provide a consistent design for many sizes and pressure ratings with straight through alignment of the single inlet and outlet ports. Other models with same-side inlet and outlet ports are also available.These transfer valves are furnished in both standard and high pressure models. NPT and weld-end models are also available. Internal channels are 100% full-flow, having the same cross-sectional area as the equivalent pipe size.

Materials of construction include cast carbon or stainless steel bodies and covers. Valve plugs are of stainless steel, bronze or cast iron. Special valve plugs can be furnished in other materials.

The valve handle guard indicates the side in use. The standard valve handle swings over the inlet port. Special reverse valve handles that swing over the outlet on flanged models can also be furnished. Drain plugs are provided in the valve chamber. An adjustable locking flange holds the valve plug on its seat on standard models. An optional lifting jack can be provided to lift the tapered valve plug off its seat for ease in valve turning in rough service on models not normally furnished with one. The lifting jack is standard on 6″ and 8″ sizes and all flanged units having a stainless steel valve plug. There are no internal linkages involved. A separate external gland is provided to allow easy access to stem packing without complete disassembly, even while in service.

The rugged, one-piece, all-cast valve housing construction avoids weld failures and potential non-uniformity of other fabricated designs.

Each valve is tested and serial numbered for accountability and traceability. The test results are provided with each valve. Special tests can also be arranged when specified.

ADJUSTABLE, TAPERED VALVE PLUG

The tapered valve plug design provides inherent compensation for wear, temperature changes and other operating variations. Metal to metal contact of sealing surfaces prolong the life of the valve, even in rough service. No special seals or seats are necessary to restore Kraissl valves to their original condition. Optional surface treatments can be furnished on valve plugs to extend life and improve sealing characteristics.FEATURES:

- Adjustable locking flange establishes valve clearance

- Independent gland adjustment for external packing access

- Tapered, all-metal valve plug for durability & renewability

- Continuous flow without changeover interruption

- Drain connection on valve chamber

- Handle indicates side in use

- Optional gage taps

- Optional lifting jack

- Optional valve plug coatings